A wide range of supporting services to manufacturing on the sites of our industrial customers.

Maintenance to production equipment

- Drafting of detailed task lists (methodologies, intervention times, production environment and safety, necessary tools, website authorizations required).

- Planning methods proven in 3 steps: monthly planning, confirmation of operations in preparatory meeting for each transaction launch permit

- Systematic consolidation of feedback

- Equipment Inventory Tracking and Calibration Services

- Full service to manage the exchange of electric motors

- Reliability Monitoring, rate analysis and causes of failures.

- Disconnection, Collection and transport to repair site (asynchronous, standard, geared motors, DC motor pumps ...)

- Project managed replacement and procurement actions

Maintenance of portable and pneumatic tools

- Corrective and preventive maintenance of portable pneumatic and electric tools (screwdrivers, riveters, sanders, seamers ...)

- Diagnostic / Repair of faulty equipment, support customer in achieving the following capabilities Q54-4000 or ISO standards.

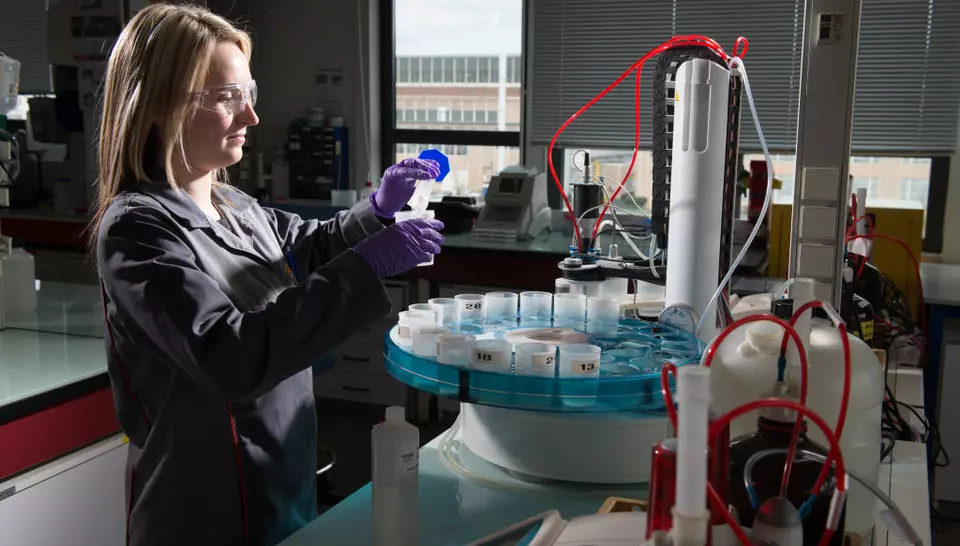

Infrared thermography and vibration analysis

- Vibration analysis (monitoring of rotating mechanical assemblies)

- Infrared thermography for electrical systems, friction analysis and detecting leaks in heat transfer.

- Ultrasonic analysis for steam leak detection.

- Noise measurements (working condition).

- Conveyor chain wear measurements.

- Various physical and electrical measurements.

Repair of logistics and specialist equipment

- Containers and trailers

- Gantry cranes

- Availability and reliability follow up

- Regulatory control

- Lifting Equipment controls